Commercial Gutters: A California Guide to Planning, Materials, and Leak Prevention

Overflowing roof runoff can stain walls, soften fascia, and create slick walkways. When commercial gutters are undersized, mis-pitched, or clogged, water finds the fastest path—usually straight over the edge.

Quick checklist:

- Decide the scope: cleaning, repair, guards, or full replacement.

- Confirm gutter size/material and how many downspouts you need for runoff.

- Plan downspout discharge and drainage so water moves away from walls, stairs, and the foundation.

- Ask whether fascia/rot repair is included and how corners/seams will be sealed.

- Compare 2–3 itemized quotes (linear feet, downspouts, guards, disposal, warranty).

- Schedule around weather and run a hose test at the final walkthrough.

This guide explains how to plan capacity, downspout layout, materials, and maintenance for California properties. Use it to ask better questions and get a written scope that matches the building.

TL;DR: Most problems trace back to slope, outlet spacing, and where downspouts discharge. Map the roof drainage, size the system for peak flow areas, and keep water moving away from the foundation. A quick water test at handoff prevents repeat leaks.

- Walk the perimeter after a rain (or hose test) and note overflow points

- Trace each roof section to the downspout that serves it

- Check hangers and seams for movement, rust, or separation

- Look for fascia/soffit soft spots that signal ongoing leaks

- Confirm where each downspout discharges and whether it needs extensions

- Decide if debris protection (screens/guards) fits the roof environment

Common Pain Points With Commercial Gutters (And Fixes)

| Decision | Why it matters | Quick check |

|---|---|---|

| Gutter size (5-inch vs 6-inch) | Capacity affects overflow risk during heavy rain. | Ask the installer to size based on roof area and runoff. |

| Downspout locations | Where water lands affects erosion and slip hazards. | Map discharge points and confirm extensions/splash blocks. |

| Guards/screens | Reduces clogs but still needs maintenance. | Choose based on debris type and confirm cleaning access. |

| Fascia condition | Weak/rotted fascia causes sagging and leaks. | Inspect before install; include repair allowance in scope. |

Commercial buildings and multi-unit properties move a lot of water. Also, When the gutter system can't keep up, runoff usually shows up where it causes the most trouble: entrances, walkways, and fascia boards.

If you own a mixed-use property, also small retail space, or multi-unit building, look for causes that affect capacity, slope, and discharge—not just a quick patch.

- Overflow during moderate rain: The system may be undersized or missing downspouts. For this reason, Upsizing the gutter profile and adding outlets often solves it.

- Water stains on walls or soffits: Back-pitch, gaps at end caps, or a drip edge feeding behind the gutter can all cause this. Correct slope and sealing matter.

- Pooling at the base of downspouts: Add extensions or route to an approved drain solution so water doesn't hammer the slab edge.

- Gutters pulling away: Loose hangers or rotted fascia won't hold. Meanwhile, Repair the wood and fasten hangers into solid framing.

- Leaking seams and corners: Re-seal or replace damaged sections; avoid layering random caulks that fail in sun and heat.

- Frequent clogs: Identify the debris type (leaves vs. As a result, grit) and match the guard/screen style to it.

- Rust or pinholes: Coatings fail, and corrosion spreads. For example, Replace badly corroded runs and avoid mixing dissimilar metals.

- Downspouts crushed by traffic: Add protection at impact zones or relocate where feasible; replace narrowed sections that restrict flow.

- Hidden rot behind gutters: Remove and inspect; repair fascia/soffit before reinstalling.

Before/After (Hypothetical Example)

Hypothetical example: A small retail building had regular overflow above the main walkway. Overall, A contractor mapped the roof drainage, replaced a short run with a higher-capacity profile, added one downspout at the true low point, and extended discharge away from the slab. The overflow stopped, and the walkway stayed drier after storms.

Planning, Budget, And Materials

A good plan starts with a roof-drainage sketch. Additionally, Even a modest commercial roof can concentrate water at valleys, parapet corners, or long straight runs.

Route Water On Purpose

Downspouts and discharge points do most of the real work. In addition, Before you pick materials, decide where the water should go.

- Mark roof planes, valleys, and any scuppers, then note the low points.

- Place downspouts at low points and add outlets on long runs to prevent bottlenecks.

- Keep discharge away from doors, loading areas, and frequently used walkways.

- Plan extensions, splash blocks, or drain tie-ins so water moves away from the foundation.

- Include cleanout access where clogs are likely (heavy trees, grit, flat roofs).

Match The Building And Exposure

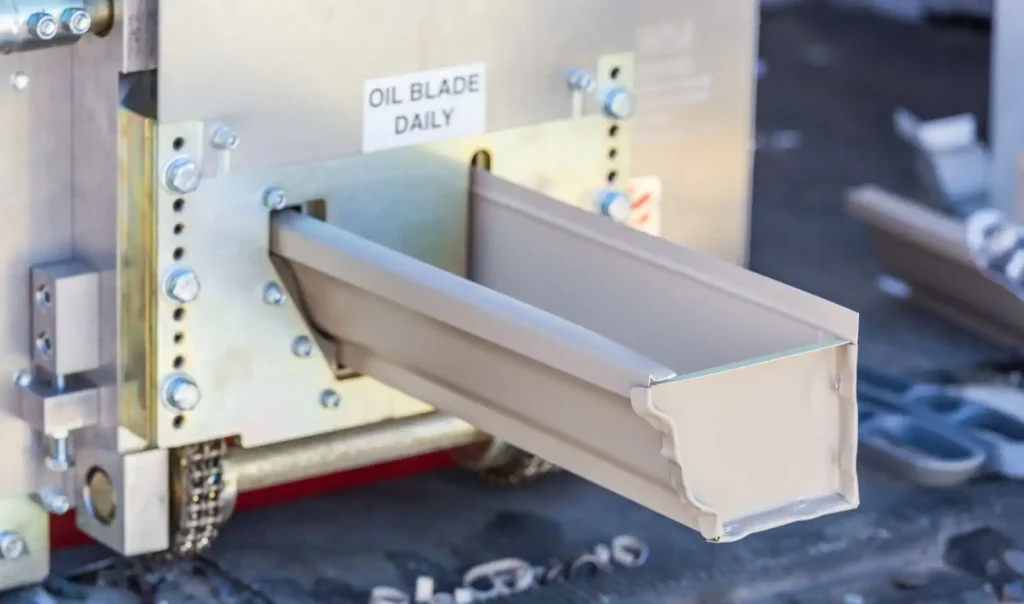

For commercial gutters, aluminum and steel are common because they support consistent profiles and reliable fastening. In addition, The right choice depends on traffic, roof height, and how often you can maintain the system.

- Aluminum: Resists rust and works well for seamless runs; it can dent in high-traffic zones.

- Galvanized steel: Strong against impacts; keep an eye on cut edges and scratches where rust can start.

- Copper: Durable and long-lasting; it costs more and needs thoughtful detailing at connections.

- Profiles: K-style and box-style profiles can handle higher volume; half-round works best when debris is lighter and slopes are steady.

- Guards/screens: Helpful in heavy leaf zones, but they must match the debris type or they create new clogs.

Quick Comparison Table

| Choice | What you're deciding | What it changes |

|---|---|---|

| Gutter size/profile | Standard vs. higher-capacity | Overflow risk and outlet count |

| Downspout layout | Fewer large vs. more frequent | Flow performance and wall staining |

| Access plan | Ladders vs. lift setup | Labor, safety, and schedule |

| Discharge method | Extensions vs. drain connection | Walkway safety and possible permitting |

Budget And Timeline (Typical)

- Minor repairs often focus on seams, outlets, hangers, and one or two damaged sections.

- Full replacement usually depends on linear footage, height/access, and how many downspouts you need.

- Discharge changes (extensions, drain connections, grading touch-ups) add scope but prevent repeat problems.

- Heavier-gauge metals and guards may raise material cost while reducing maintenance.

Cleaner Maintenance And Water Capture

Some add-ons pay off by reducing cleanup time and keeping runoff predictable around the site.

- Downspout cleanouts support fast flushing during maintenance.

- Strainers at outlets help block large debris before it enters a downspout.

- Rain barrels or cistern connections can work in some settings; plan an overflow path so water still exits safely.

- Drip edges and splash protection reduce hidden rot at fascia and wall lines.

If you're comparing bids, ask each contractor to state the gutter size/profile, downspout count, hanger spacing, and discharge plan in writing.

Timeline And Permit Considerations

US Construction & Remodeling Corp. Additionally, helps Sacramento-area owners plan commercial gutters with the right capacity, safe access, and a clear discharge plan—so the work stays predictable and the site stays safe.

Schedule online for a free estimate and we'll review your roofline, measure runs and downspouts, and provide a written scope. Additionally, If you prefer to talk first, call +1 (916) 234-6696.

How A Commercial Gutter Project Usually Runs

- Site walk + measurements: Identify overflow points, measure linear footage, and note heights/access needs.

- Drainage layout confirmation: Decide downspout locations, outlet sizing, and where water will discharge.

- Material/profile selection: Choose the gutter profile, metal, finish, and any guard/screen approach.

- Prep and repairs: Address fascia/soffit damage and remove sections that can't be salvaged.

- Install + water test: Set slope, secure hangers, seal connections, and test flow before cleanup.

California-Specific Scheduling Realities

In many parts of California, the long dry season lets leaves and grit build up quietly. Additionally, The first heavy rain is often when owners notice overflow, which is why an inspection before the rainy season can prevent emergency work.

When Permits Might Apply

Many gutter repairs stay in the maintenance lane. For example, Still, permitting can come up when you change structural elements, modify roof drainage, or connect downspouts into certain drainage systems. Rules vary by city and county, so confirm requirements for the property address before work begins.

- Structural wood repair at fascia/soffits beyond minor patching

- New roof penetrations, scupper changes, or drainage re-routing

- Connections to storm drain systems (or similar site drainage work)

Frequently Asked Questions

A commercial gutter system usually serves a larger roof area and longer runs than a typical home. Because of that, sizing, fastening, and discharge planning matter more than appearance.

- Larger profiles (often box-style) and more outlets

- Downspouts sized and placed for valleys and true low points

- Heavier hangers/fasteners where spans and wind loads increase

- Access planning (lifts, walkway protection) for multi-story work

Overflow in one spot usually points to a bottleneck. Look for staining below valleys, gutters that hold water after a storm, or erosion where one downspout dumps most of the flow.

A contractor can run a controlled water test and confirm whether adding outlets, upsizing downspouts, or changing placement will solve the problem.

It depends on what changes. In-kind replacement and minor sealing often stay in maintenance, while structural wood repair, new roof-drainage openings, or certain drain connections may require permits.

Check requirements with the city or county permitting office for the property address. In Sacramento, many steps can be tracked online through Accela Citizen Access.

Aluminum is common for seamless runs and resists rust. Steel handles impacts better but needs good coating care to prevent corrosion. Copper lasts a long time and develops a patina, but it costs more and needs compatible metals at connections.

The best choice matches the building exposure, traffic risk, and how often you plan to inspect and clean the system.

Cost usually follows scope and access more than any single material choice. Ask bidders to show these items in writing so you can compare accurately.

- Total linear footage and gutter profile size

- Height, access method, and safety setup

- Downspout count, outlet sizing, and discharge extensions

- Fascia/soffit repairs discovered during removal

- Guards/screens and any custom color or heavier-gauge metal

Cleaning frequency depends on trees, roof type, and debris. Many California properties schedule a clean-out before the rainy season and again mid-season, with an extra check after heavy wind.

Guards can reduce large debris, but they still need inspection so smaller grit doesn't create hidden clogs.